I. Product Details

Augfu Technical Specification for 'Pioneer' Series Large Industrial Fans

|

Propeller blades only need to rotate slowly in the air to form a continuous, silent breeze flow. Unique and efficient airfoil blades rotate slowly to generate a large amount of downward air flow, thus forming a nearly perfect propeller exhaust. |

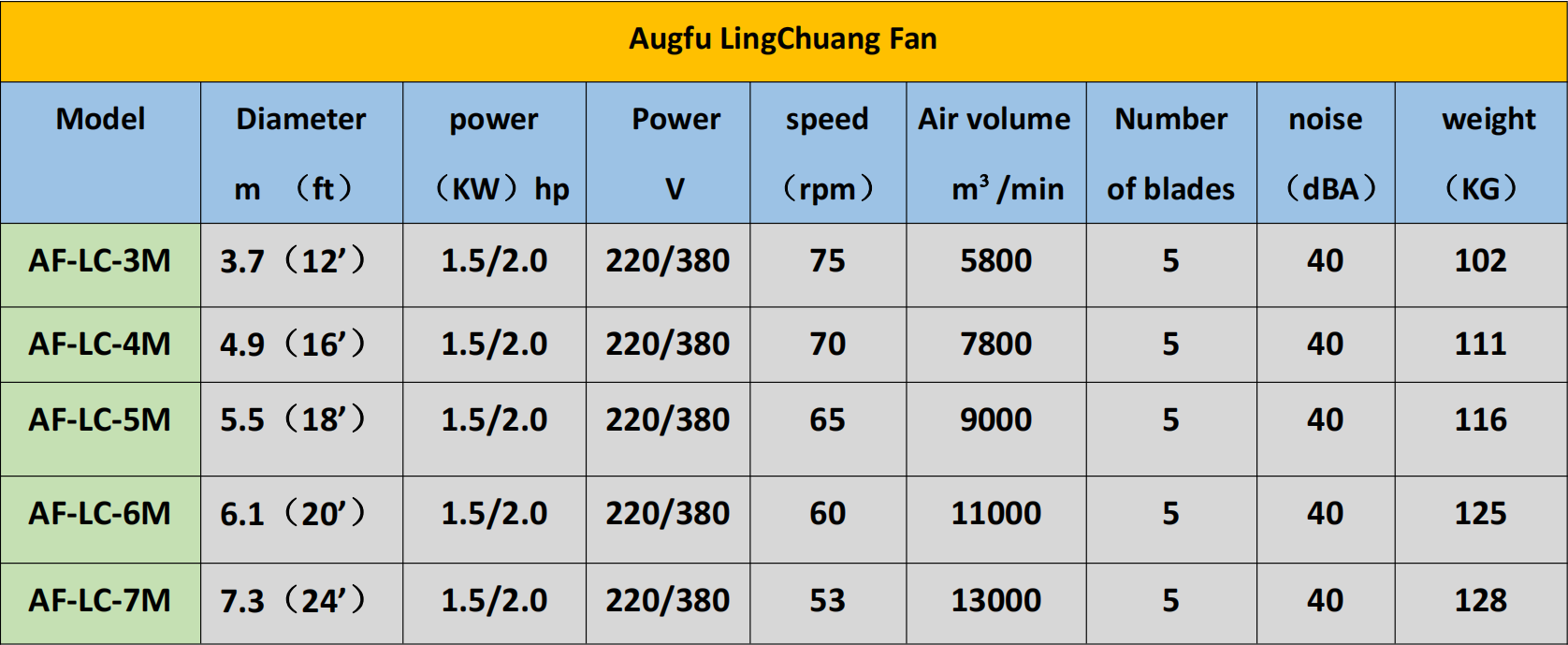

1. Model Specification Parameters

Model Specification AF-LC-7M

operation---------------------------------------Forward turn operation

Fan diameter---------------------------------------7.3Meters

Converter disc - Aluminum alloy forged fan hub, imported American Airlines AA7075 superhard aluminum alloy, high-pressure precision forging

Fan leaf material----Adopt high strength 6063 series, one-time extrusion forming, built-in three reinforcing bars

Fan leaf---------------------------------------------------------5 tablets

Rated power------------------------------------------ 2.0 HP 1.5 kW

Installed weight---------------------------------------------------130 Kg

2. Performance specification parameters

Performance (maximum speed) AF-LC-7M

Circulating air volume-----------------------------------13,000 CMM( m3min)

Maximum speed--------------------------------------------- 20-53 RPM

Power consumption per hour at maximum speed----------------------------------1.5 kW

Typical layout spacing---------------------------------------30 rice Meters

Maximum noise--------------------------------------------------45 Decibel

Note: * Noise value is the factory test value, and there will be slight change in each application condition. The motor is German Nord Motor, the frequency converter is Danish Danfoss brand, and the motor and frequency converter are imported brands.

3. Other specifications and parameters

Install fixtures

Standard configuration-------------------------------General clamping device for I-shaped steel beam

Concrete Beam Clamp Structure (Selection) Extension Bracket (Selection)----------------The longest is 5 meters.

Motor power HP ------------------------------ 2HP 1.5 kW

ambient temperature-------------------------------------20C°-+45C°

Insulation grade------------------------------------------------ F

Protection level---------------------------------------------IP 55

Work system-------------------------------------------------S 1

power factor------------------------------------------- 0.8.78

Gearbox

Model:Type---------------------------------------2-Stage Helical

Lubricant Maintenance Period Service Interval---------------Shell Top Omala S4GX Synthetic Gear Oil with Extra Long Service Life

Control box(MCP)

Standard Power Configuration-------------------------------------------220V/380

Box body----------------------------------------IP55 Protection Level NEMA 1

Power Indicator Lamp-------------------------------------------Stop running status

Isolating switch-------------------------------20-25 Amp, Lockable Lockable

Switch and Speed Control Button------------------NEMA 4X -Positive Stop Reverse Installation

RF filter------------------------------Preventing interference with other equipment- Built In

Frequency Conversion Soft Start-----------Stepless Speed Regulation, Reduction and Deceleration Limitation and Minimum Speed Limitation

Frequency converter-----------------------------VLT Automation Drive 1.5KW)|380V220V

Frequency Converter Cable------------------------------- RVV3*2.5+1*1.5----- 50 Meters